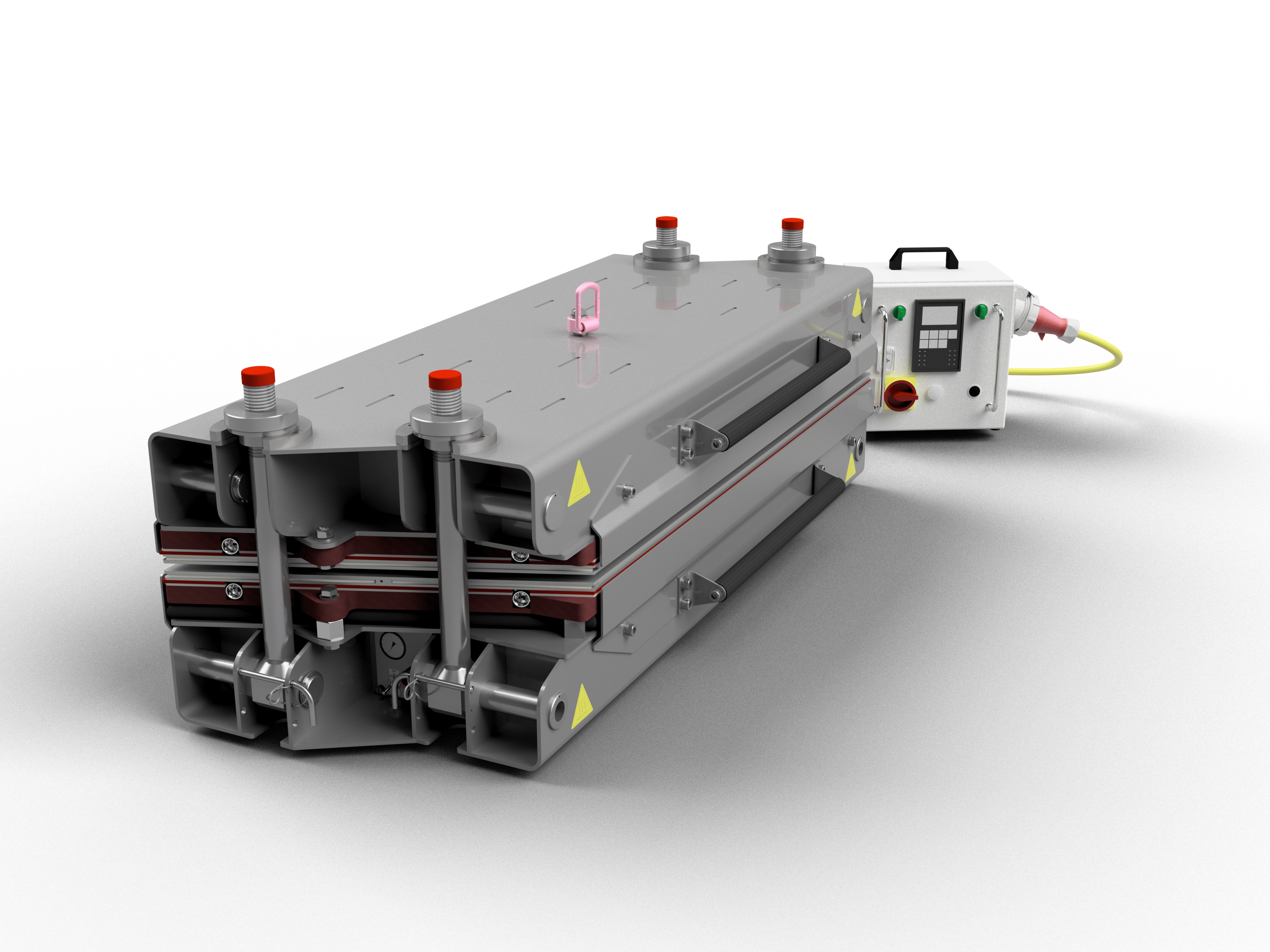

Lightweight two-piece vulcanizing press with integrated control system and a maximum platen length of 810mm, suitable for belt widths from 650mm to 1600mm using a maximum pressure of 100Psi on a bias of 22°.

• Welded aluminum frame construction

• Heating platen with silicone heating element

• Sturdy aramid-reinforced pressure bag

• Electronic temperature control

• Adjustable temperature up to max. 175° C

• Incorporated air control unit with safety valve and pressure gauge

• Heating platen equipped for air or water cooling

• Rapid heat up and cool down time

• Quick assembly and disassembly

• Easy to disassemble tension bolts

• Multiple units can be used side by side for longer splice lengths

• Voltage: 230V / 400V / 480V, 50/60Hz, 3Ph+N+PE (other voltages on request)

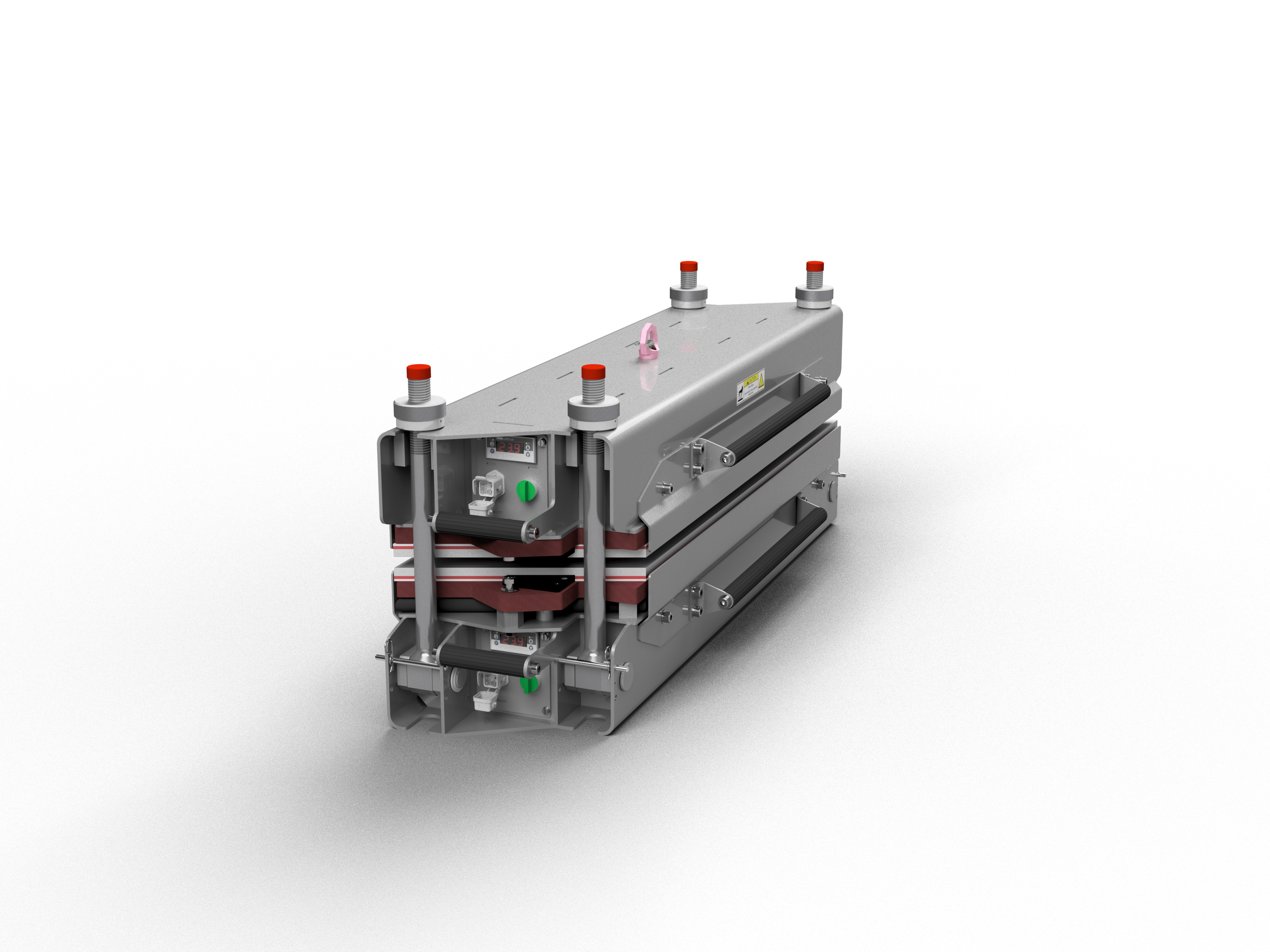

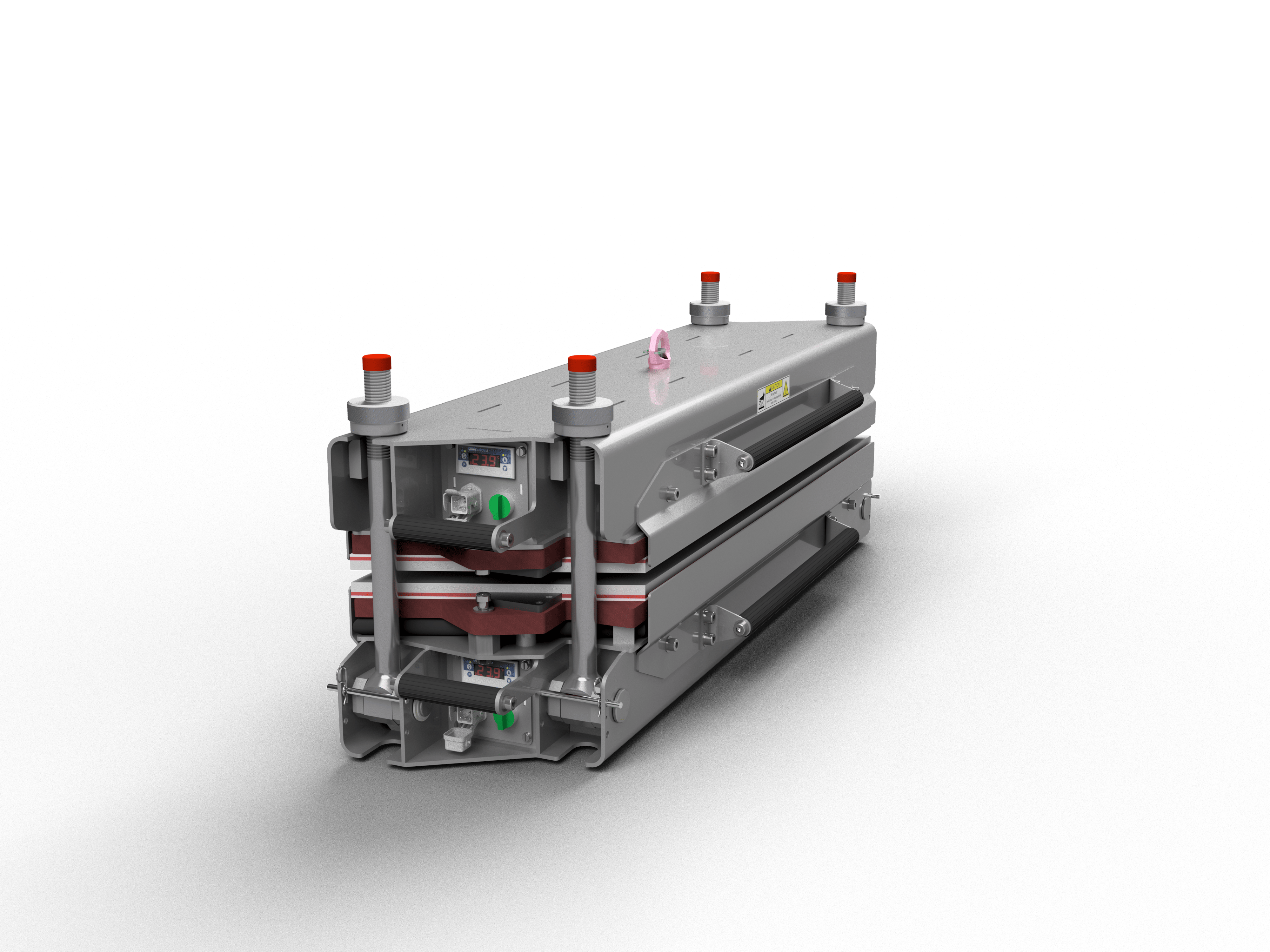

Vulcanizing press type VULCOLITE XL

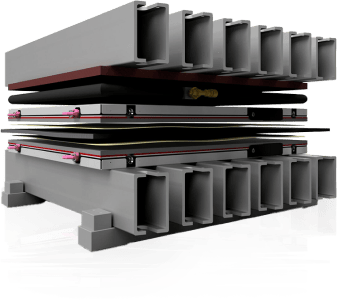

Two-piece press with heating system in sandwich construction (silicone heating element) and pressure bag system.

- Suitable for belt widths 900-1600mm.

- Heating length of 810mm.

- Heating platen with silicone heating elements.

- Two-piece aluminum construction for quick assembly and disassembly.

- Extremely short heating and cooling time.

- Heating platen equipped for air or water cooling.

- Specific pressure: 70N/cm² (100psi).

- Easy and fast pressure build-up by compressed air.

- Integrated air control unit with pressure gauge and safety valve.

- Aramid-reinforced pressure bag.

- Fully integrated electrical control box in frame.

- Electronic temperature control for set and actual temperature monitoring of both heating platen.

- For longer joint lengths, several press sections can be arranged side by side without assembly work.

- Voltage: 400V, 50/60Hz, 3Ph+N+PE (other voltages on request).

- Traction bolts do not longer protrude above the upper edge of the press.

- Traction bolts can be swiveled in - with the same belt thickness, it is no longer necessary to screw on and off when opening the press.

- The total weight has been reduced by approx. 15 % despite the strong design.

- Maximum pressure currently 7 bar - air pressure exchanged.

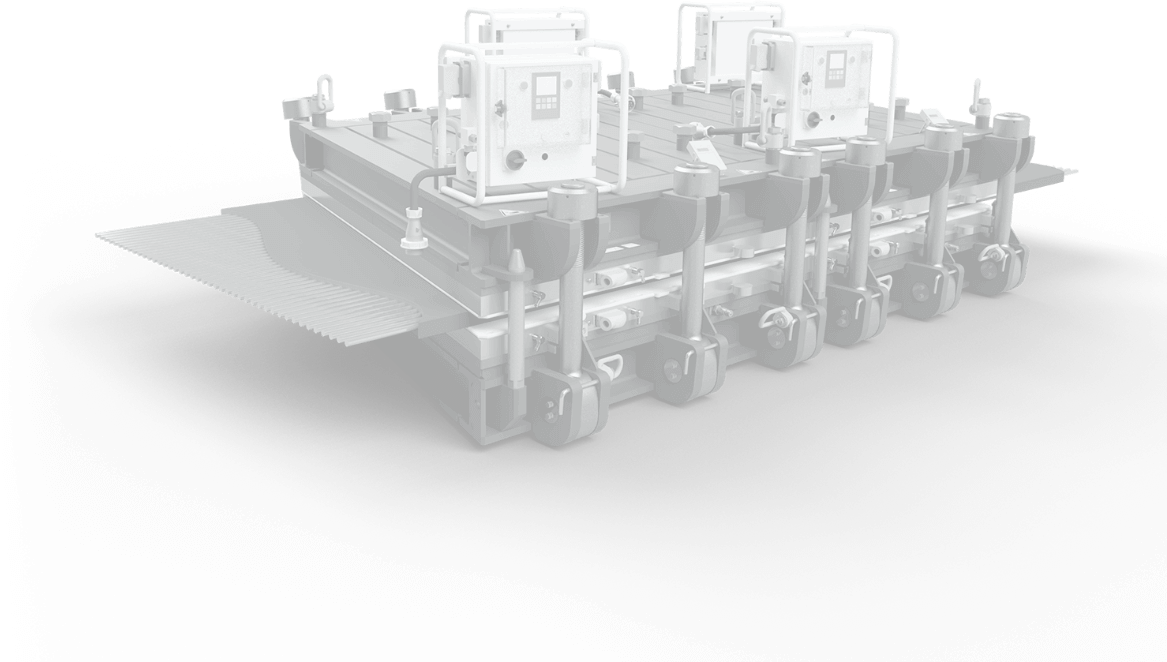

Vulcanizing press type VULCOLITE FL

Two-piece press with heating system in sandwich construction (silicone heating element) and pressure bag system

- Suitable for belt widths 650-1600mm.

- Heating length of 540mm.

- Two-piece aluminium construction for quick assembly and disassembly.

- Design rhombic 22° / 90°.

- Heating platen with silicone heating element.

- Extremely short heating and cooling time.

- Heating platen equipped for air or water cooling.

- Adjustable temperature from 100 - 175°C.

- Specific pressure: 70N/cm² (100psi).

- Simple and fast pressure build-up by compressed air.

- Integrated air control unit with pressure gauge and safety valve.

- Aramid-reinforced pressure bag.

- Sturdy, easy-to-use electrical control box (extern).

- Electronic temperature control with digital display for set and actual temperature monitoring of both heating platen.

- For longer joint lengths, several pr›ess sections can be arranged side by side.

- Voltage: 400V, 50/60Hz, 3Ph+N+PE (other voltages on request).

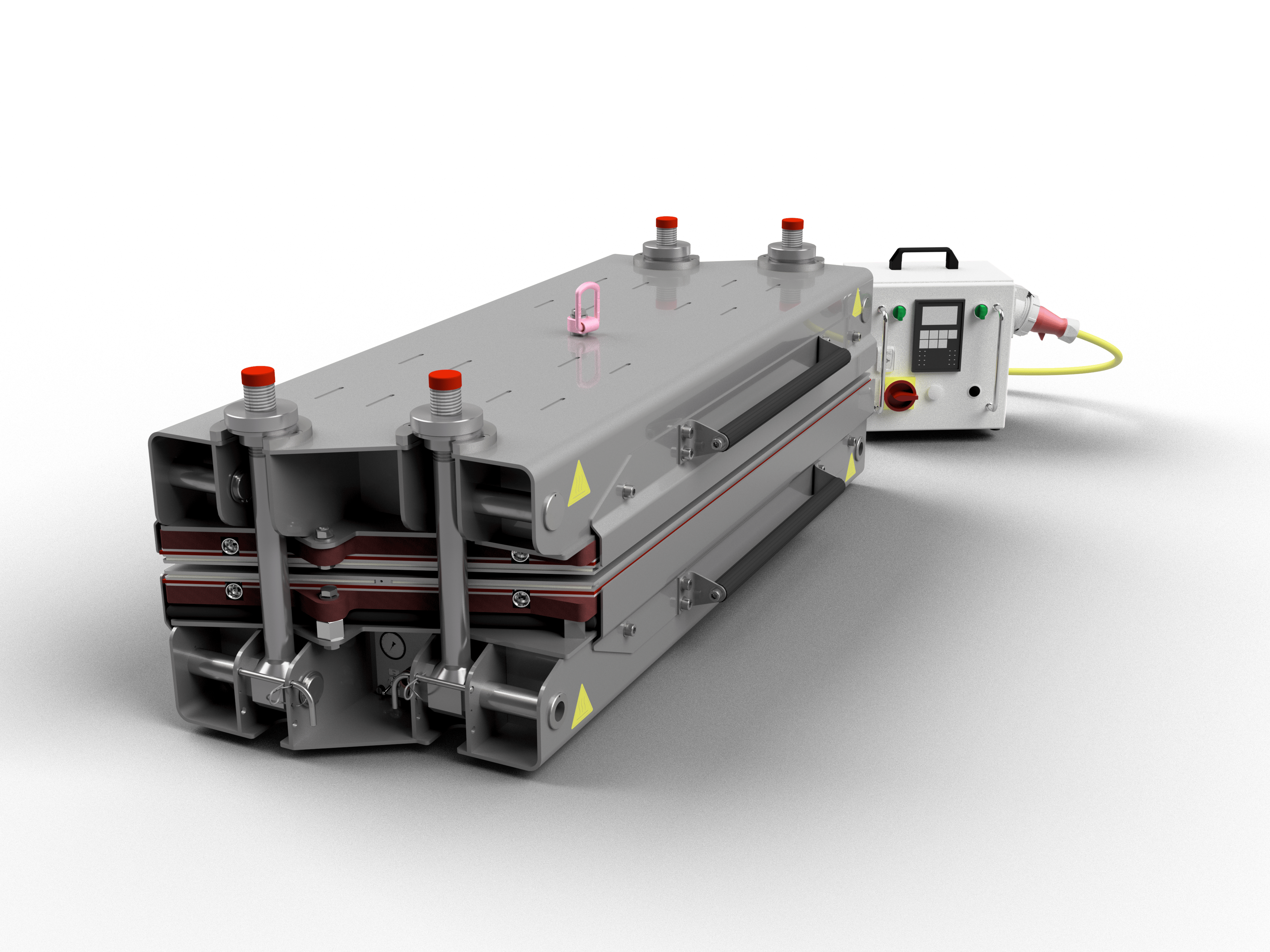

Vulcanizing press type VULCOLITE S

Two-piece press with heating system in sandwich construction (silicone heating element) and pressure bag system

- Suitable for belt widths 650-1200mm.

- Heating length of 350mm.

- Two-piece aluminum construction for quick assembly and disassembly.

- Design rhombic 22°.

- Heating platen with silicone heating element.

- Extremely short heating and cooling time.

- Heating platen equipped for air or water cooling.

- Adjustable temperature from 100 - 175°C.

- Specific pressure: 70N/cm² (100psi).

- Simple and fast pressure build-up by compressed air.

- Integrated air control unit with pressure gauge and safety valve.

- Aramid-reinforced pressure bag.

- Fully integrated electrical control box in frame.

- Integrated electronic temperature control with digital display to control the heating platen.

- For longer joint lengths, several press sections can be arranged side by side.

- 400V, 50/60Hz, 3Ph+N+PE (other voltages on request).

Vulcanizing press type VULCOLITE SL

Two-piece press with heating system in sandwich construction (silicone heating element) and pressure bag system

- Suitable for belt widths 800-1600mm.

- Heating length of 350mm.

- Two-piece aluminum construction for quick assembly and disassembly.

- Design rhombic 22°.

- Heating platen with silicone heating element.

- Heating platen equipped for air or water cooling.

- Adjustable temperature from 100 - 175°C.

- Specific pressure: 50N/cm² (70 psi).

- Simple and fast pressure build-up by compressed air.

- Integrated air control unit with pressure gauge and safety valve.

- Aramid-reinforced pressure bag.

- Fully integrated electrical control box in frame.

- Integrated electronic temperature control with digital display to control the heating platen.

- For longer joint lengths, several press sections can be arranged side by side.

- 400V, 50/60Hz, 3Ph+N+PE (other voltages on request).