FECON belt clamping system

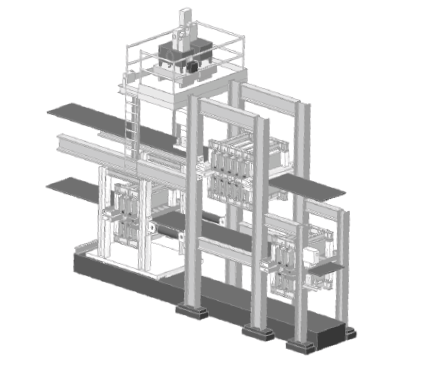

When employed in heavy-duty belt conveyors, such as those found in iron ore and coal mines, belt clamping systems must withstand significant tensile forces. Every clamping operation must prioritize the correct handling of these high-strength and valuable conveyor belts to prevent any potential damage.

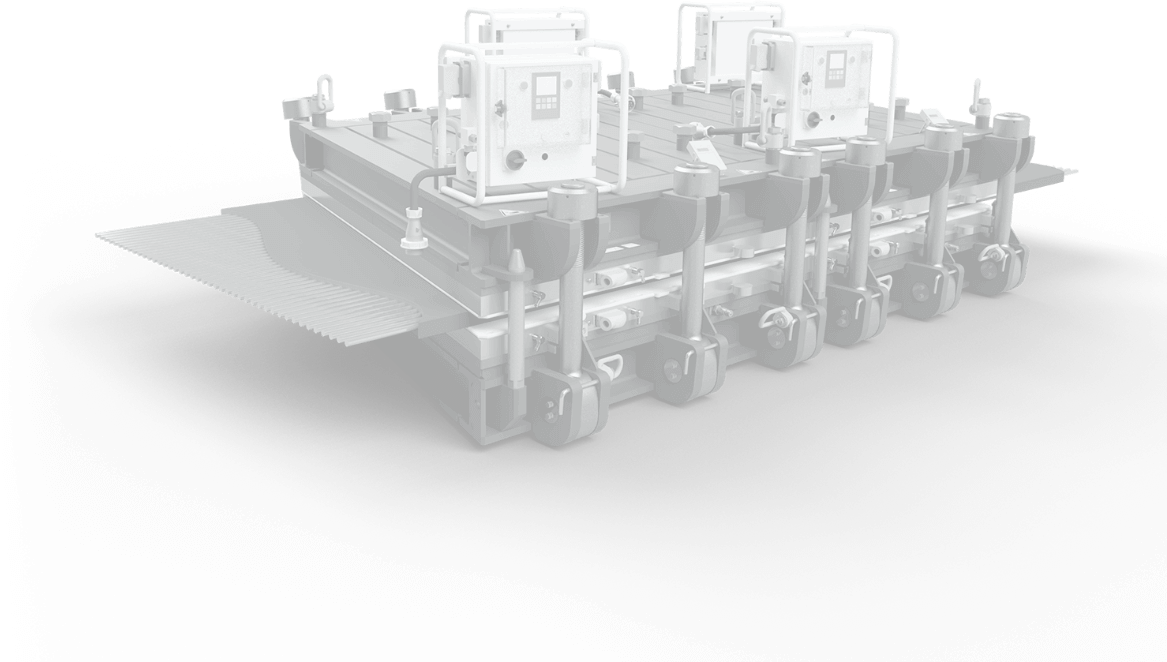

WAGENER Vulcanizers’ clamping systems accommodate belts with widths up to 2400 mm and can exert holding forces ranging from 100 kN to 2000 kN. This ensures that even fully loaded belts can be securely held in position during emergencies. These clamps are designed to maintain their grip under challenging operating conditions, and, if needed, can be customized to facilitate the safe insertion of belts into the conveyor system.

The FECON belt clamps are specifically engineered to handle the distinct challenges posed by belt conveyors experiencing high descending forces.

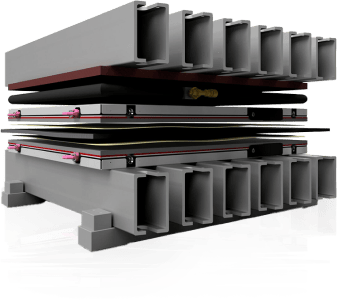

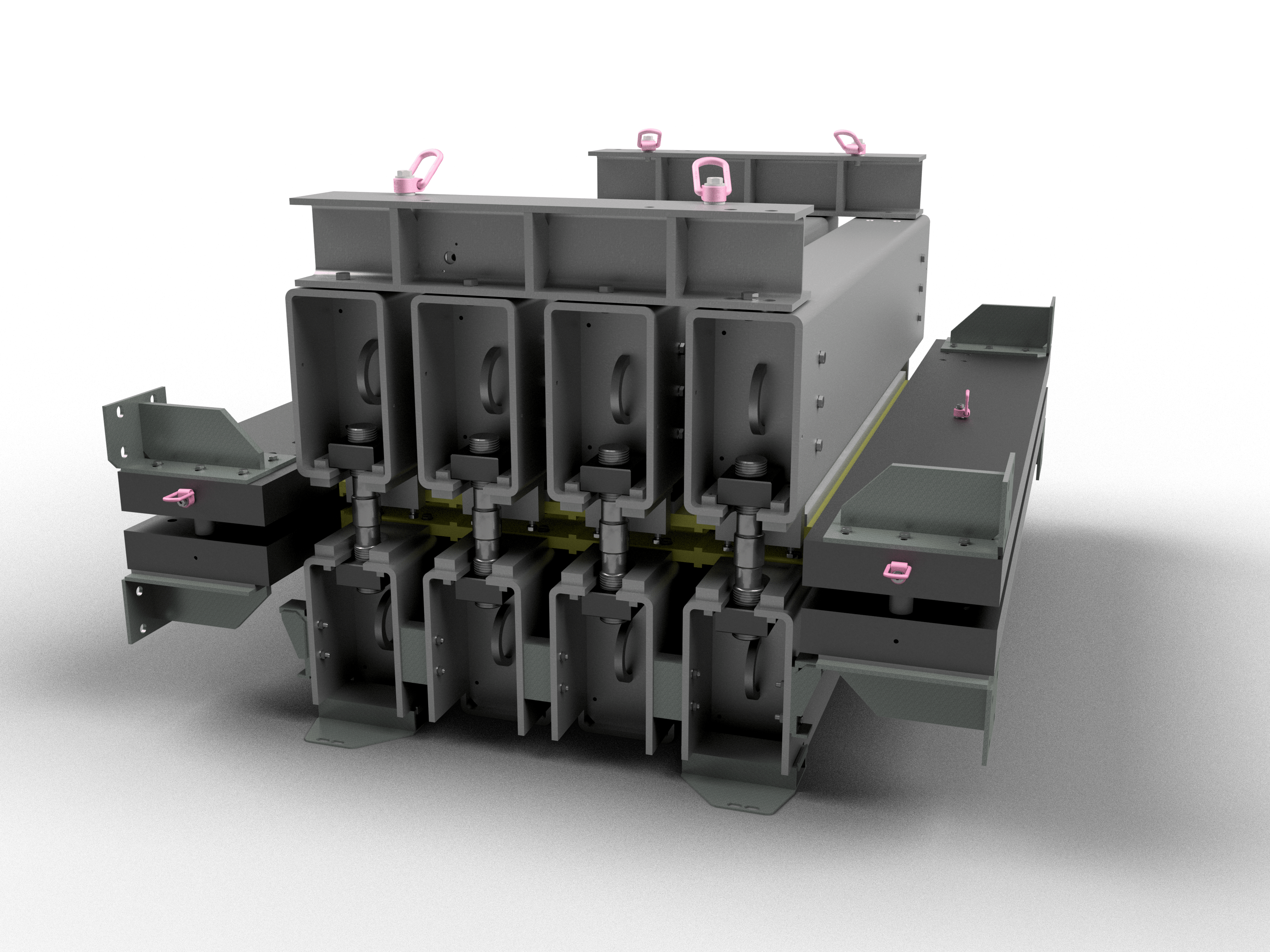

FECON clamps utilize disk springs to deliver the necessary clamping force, while hydraulic pistons facilitate the opening of each clamping section. Thanks to their fail-safe design, these clamps automatically secure within two seconds during electrical or hydraulic malfunctions. Additionally, for precise belt installations, an optional control device for fine-tuning belt speed is available.

- Uniform surface pressure over the entire belt width.

- Application of the clamping force by several independent clamping sections, each acting on a pair of clamping jaws.

- Separation of vertical clamping force and horizontal belt holding force.

- Clamping jaws equipped with ceramic friction lining to ensure a high coefficient of friction and belt tensioning areas.