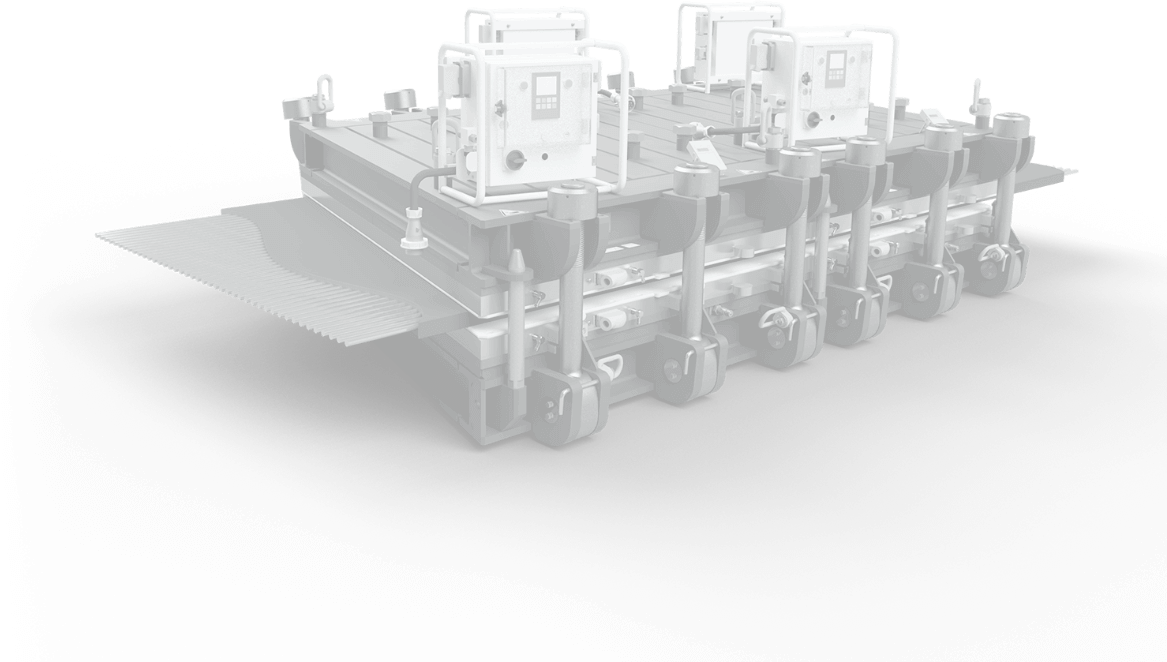

Premium-quality, durable pressure bags compatible with all heating platen sizes and brands.

WAGENER Vulcanizers pressure bags offer distinct advantages over competitors:

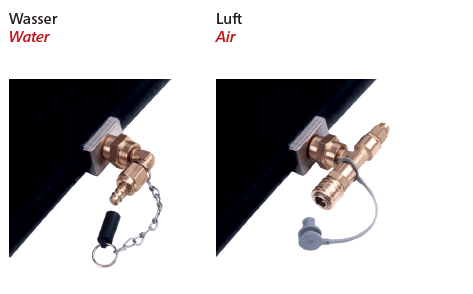

1) Each pressure bag features a vulcanized stainless-steel insert. This ensures that the bag’s connection is safeguarded from compression and obstruction.

2) This stainless-steel insert also guarantees an exceptional seal between the pressure bag, head plate, and lock nut.

3) Our pressure bag connection boasts a compact design. This design ensures the connection hose consistently sits behind the traction bolts, allowing the bag’s position to remain unaffected by the number or placement of these bolts.

4) Our durable and long-lasting connection can be tailored to unique customer specifications. Nevertheless, we advocate for our standard connections, suitable for both Air and Liquid, to ensure optimal performance.

5) Manufactured with premium rubber and fortified with Aramid reinforcement, our pressure bags are designed for longevity.

6) Lastly, we take pride in the fact that all our pressure bags are MADE IN GERMANY.

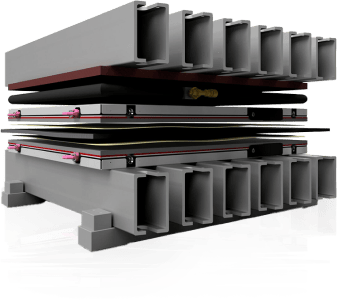

- Aramid-reinforced pressure bag

- Certified for safety and quality by the renowned TÜV authority in Germany

- Shape: rhombic 16°, 42°; rhombic 22°, rectangular 90°

- The pressure bag design ensures a uniform pressure distribution

- Air pressure, water, or a water/glycol mixture can be utilized as pressure mediums

- When utilizing air pressure, the maximum surface pressure is 70 N/cm2 (100 psi)

- When using water or a water/glycol mixture, the surface pressure can reach up to 140 N/cm2 (200 psi)