Calibration Procedure for WAGENER EMU Vulcanizing Presses: A Technical Overview

WAGENER EMU vulcanizing presses are known for their robust design and superior technology, making them a preferred choice in the belt splicing and conveyor industry. One of the standout features of these presses is the minimal need for calibration, thanks to their advanced engineering. This article will discuss the calibration procedure for WAGENER EMU vulcanizing presses, emphasizing the conditions under which calibration is generally unnecessary.

The Role of Calibration in Vulcanizing Presses

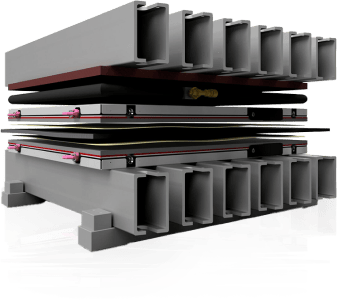

Calibration in vulcanizing presses typically ensures that the heating elements deliver consistent and accurate temperature control across the platen surface. This uniformity is crucial for achieving a strong and reliable vulcanization process. However, calibration can be a time-consuming and technical task, often requiring specialized equipment and expertise.

Why WAGENER EMU Vulcanizing Presses Require Minimal Calibration

The WAGENER EMU series is designed with cutting-edge technology that significantly reduces the need for frequent calibration. The key factors contributing to this are:

- High-Quality Heating Elements:

– The heating elements in WAGENER EMU presses are engineered to provide consistent performance over long periods. Manufactured using CNC technology WAGENER elements are less prone to the drift in temperature output that typically necessitates recalibration.

– As long as the heating elements remain in good health, meaning they have not deteriorated or become damaged they maintain their accuracy, rendering recalibration unnecessary.

- Reliable PT100 Sensors:

– Each heating platen is equipped with PT100 sensors, which are platinum resistance thermometers known for their accuracy and stability. These sensors continuously monitor the temperature, ensuring it remains within the desired range.

– WAGENER PT100 sensors are securely fastened directly to the platen surface, providing consistent and reliable temperature readings. In contrast, our competitors place their sensors in a hole filled with conductive grease, which can degrade over time and compromise accuracy.

– As long as the PT100 sensors are healthy and functioning correctly, they provide reliable data to the system, maintaining the press’s optimal operation without the need for recalibration.

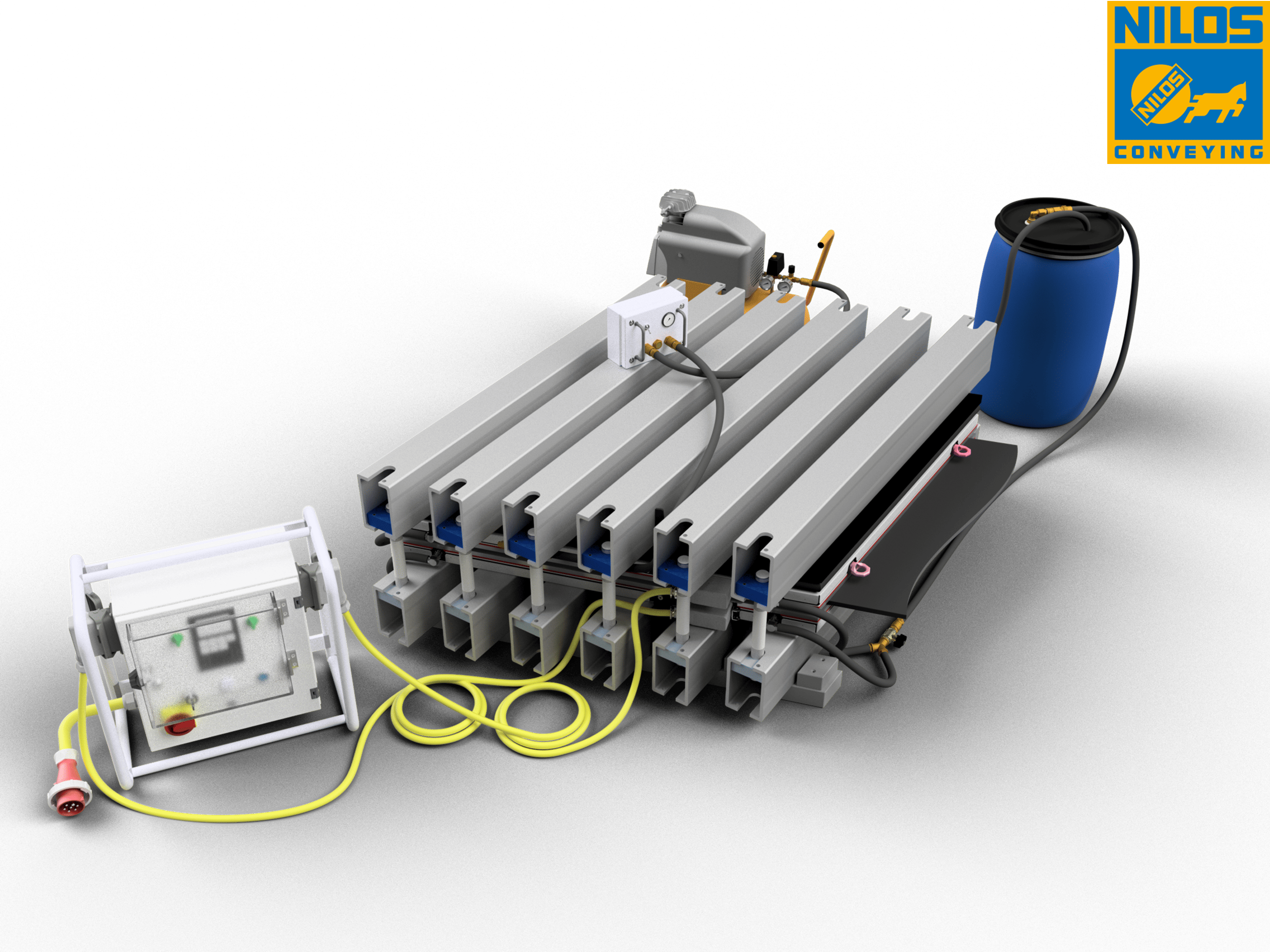

- Durable MCC Controller:

– The WAGENER EMU presses utilize an MCC (MultiControl Compact) controller within the control box, which is responsible for regulating the heating process based on the input from the PT100 sensors.

– The MCC controller is designed to withstand harsh operational environments, and as long as it is not faulty or damaged, it ensures precise control over the vulcanization process. The durability of the MCC controller means that once the system is initially calibrated, it does not require frequent recalibration, provided the controller remains in good condition.

Ensuring System Health for Calibration-Free Operation

While the WAGENER EMU presses are designed to minimize the need for calibration, it is essential to ensure that the critical components—the heating elements, PT100 sensors, and MCC controller—are in good health. Regular inspections and maintenance of these components can help avoid unexpected issues:

– Heating Element Check: Periodically inspect the heating elements for signs of wear or damage. Any significant deviations in performance could indicate the need for replacement.

– PT100 Sensor Verification: Ensure that the PT100 sensors are clean and free from damage. A malfunctioning sensor can cause temperature inaccuracies.

– MCC Controller Integrity: Regularly check the MCC controller for any signs of physical damage or malfunction. If the controller is compromised, it could affect the overall operation of the press.

Conclusion

The WAGENER EMU vulcanizing presses are designed with superior technology that largely eliminates the need for regular calibration. As long as the heating elements, PT100 sensors, and MCC controller remain in good working condition, the system operates efficiently and accurately without the need for frequent recalibration. This not only saves time and resources but also ensures consistent and reliable performance in the field. Regular maintenance of these components is the key to maintaining the calibration-free operation of WAGENER EMU presses.

Prepared by:

KARSTEN VÖLZKE

22/8/2024