REPAIR PRESS - TYPE EDGEFRAME

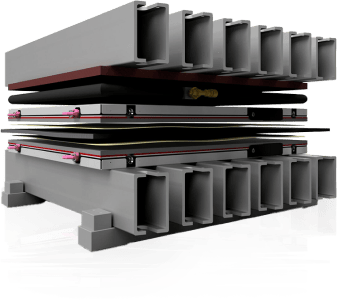

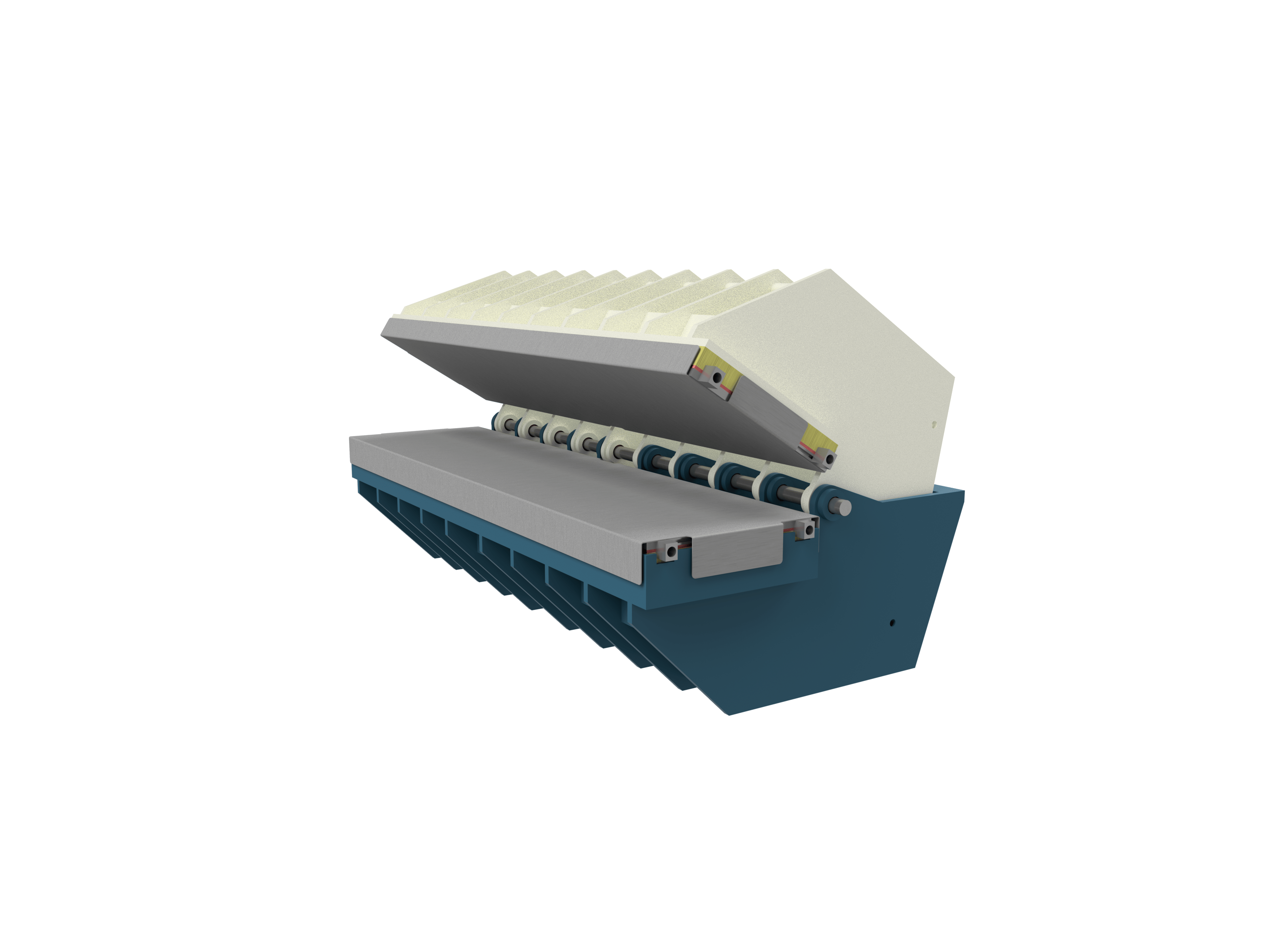

One-piece design for edge repairs with heating system in sandwich construction (silicone heating element) and pressure bag system

- Compact edge repair press in light- weight aluminum design

- One-piece press in welded frame construction made of high-alloy aluminum

- Press with swiveling upper part

- Easy swiveling of the upper part due to the support of a gas pressure spring

- Integrated EMU heating platen for electronic temperature control and water cooling

- Integrated pressure bag in the lower part for surface pressure of 70N/cm? (100psi).

Heating Length

750mm | 29 ½"

Heating Width

300mm | 12" x 12"

Belt Thickness Max.

38mm | 1,5"

Surface Pressure

70 N/cm² (100psi)

Pressure Medium

Air Pressure

Vulc. Temperature Max.

175°C | 347°F

Nominal Power Approx.

3 kW (2 x 1,5kW)

Voltage

400V, 50Hz, 3Ph

Weight

145 kg | 320 lbs

Heating Length

1200mm | 48"

Heating Width

300mm | 12" x 12"

Belt Thickness Max.

38mm | 1,5"

Surface Pressure

70 N/cm² (100psi)

Pressure Medium

Air Pressure

Vulc. Temperature Max.

175°C | 347°F

Nominal Power Approx.

4,7 kW (2 x 2,35kW)

Voltage

400V, 50Hz, 3Ph

Weight

240 kg | 529 lbs