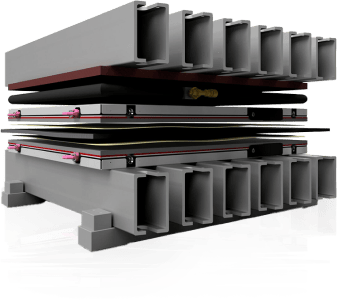

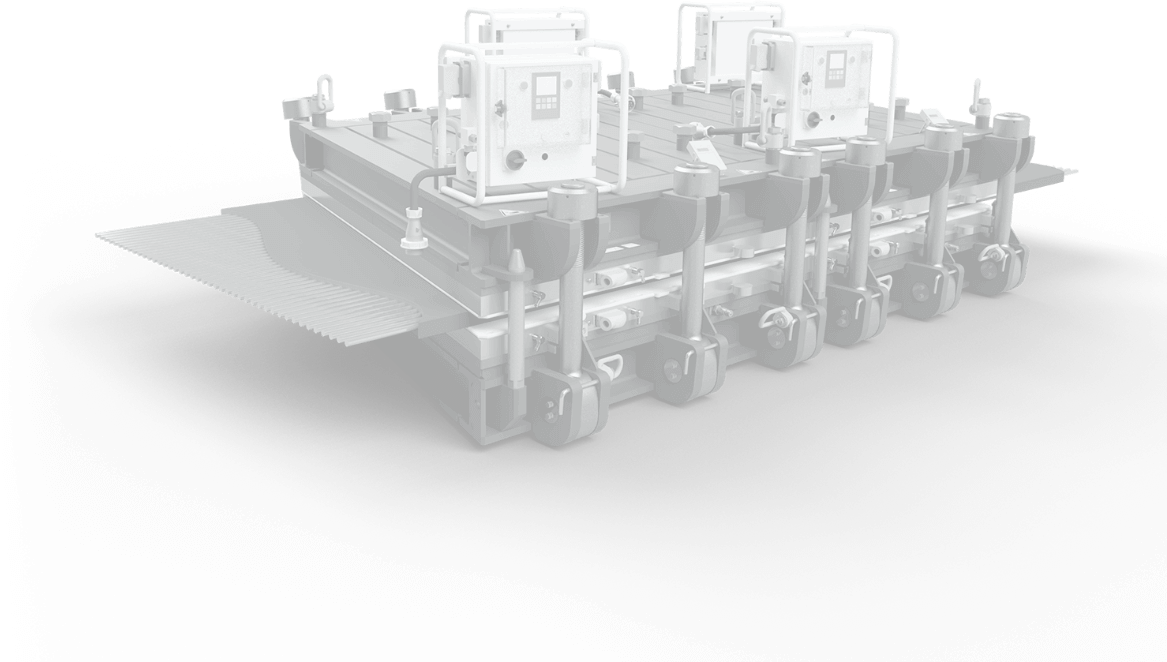

WAGENER Vulcanizers Conveyor Belt Pulling Plates (CBPP), also known as belt pullers or belt grip plates, are devices used in conveyor systems to facilitate the installation, replacement, and maintenance of conveyor belts. These plates offer several advantages that make them a safe, valuable tool in the installation of conveyor belt in the Australian Mining Industry:

Improved Safety.

WAGENER Vulcanizers treats safety as a top priority in the Australian Mining Industry. CBPP’s provide a workload limited (WLL), safe, and controlled way to secure and install heavy duty fabric, solid woven and steel cord conveyor belts. CBPP reduces the risk of accidents and injuries during installation or maintenance.

Precise Alignment.

WAGENER Vulcanizers CBPP’s enable a measured, safe, precise mode of pulling the leading belt end, ensuring safe, effective installation. This ensures that the belt runs smoothly and does not veer off track, reducing the need for frequent adjustments, increasing safety to people and plants.

Reduced Belt Damage.

WAGENER Vulcanizers CBPP are WLL and fit for purpose. They distribute the force evenly, minimizing the risk of belt deformation, tearing, or stretching.

Compliance with Safety Standards.

WAGENER Vulcanizers CBPP’s are WLL, qualified and certified to comply with safety regulations and standards, as they promote safer and more controlled handling of the conveyor belt.

In summary, CBPP offers numerous advantages, including improved safety, enhanced efficiency, precise alignment, reduced belt damage, and cost savings. Their use not only benefits workers but also contributes to the overall productivity and reliability of conveyor systems in the Australian Mining Industry.