VULCANIZING PRESS TYPE EMU

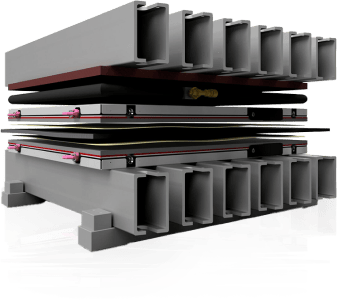

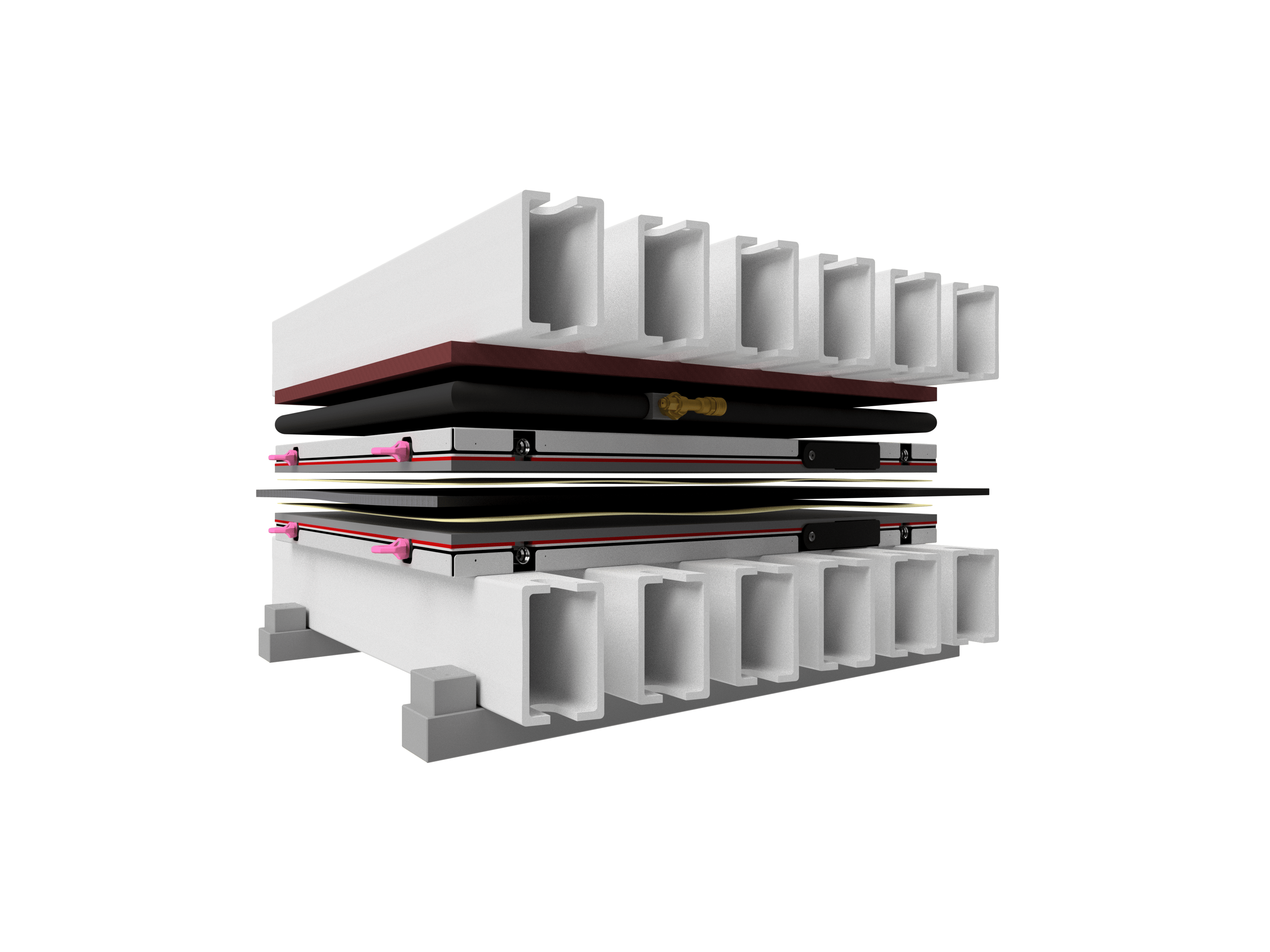

The WAGENER EMU Sectional press is designed with a heating system in sandwich construction including silicone heating elements and pressure bag system. This design offers portability and adaptability to various sizes, making it suitable for all splice lengths or belt widths. Individual components are lightweight and straightforward to put together. These presses can be broken down into separate parts for transportation.

- Light construction for flexible use

- Equipped for water / air cooling

- Robust, flush fitting electric connections with a metal plug locking device

- Quick heating time with optimum heating capacity

- Quick cooling time due to integrated cooling channels

- Optimum pressure and temperature distribution

- Optional safety restraints and lifting lugs for traverse bars / cross beams.

- Compliance to Australian Standards including AS3007, AS4871 and MDG15 is available.

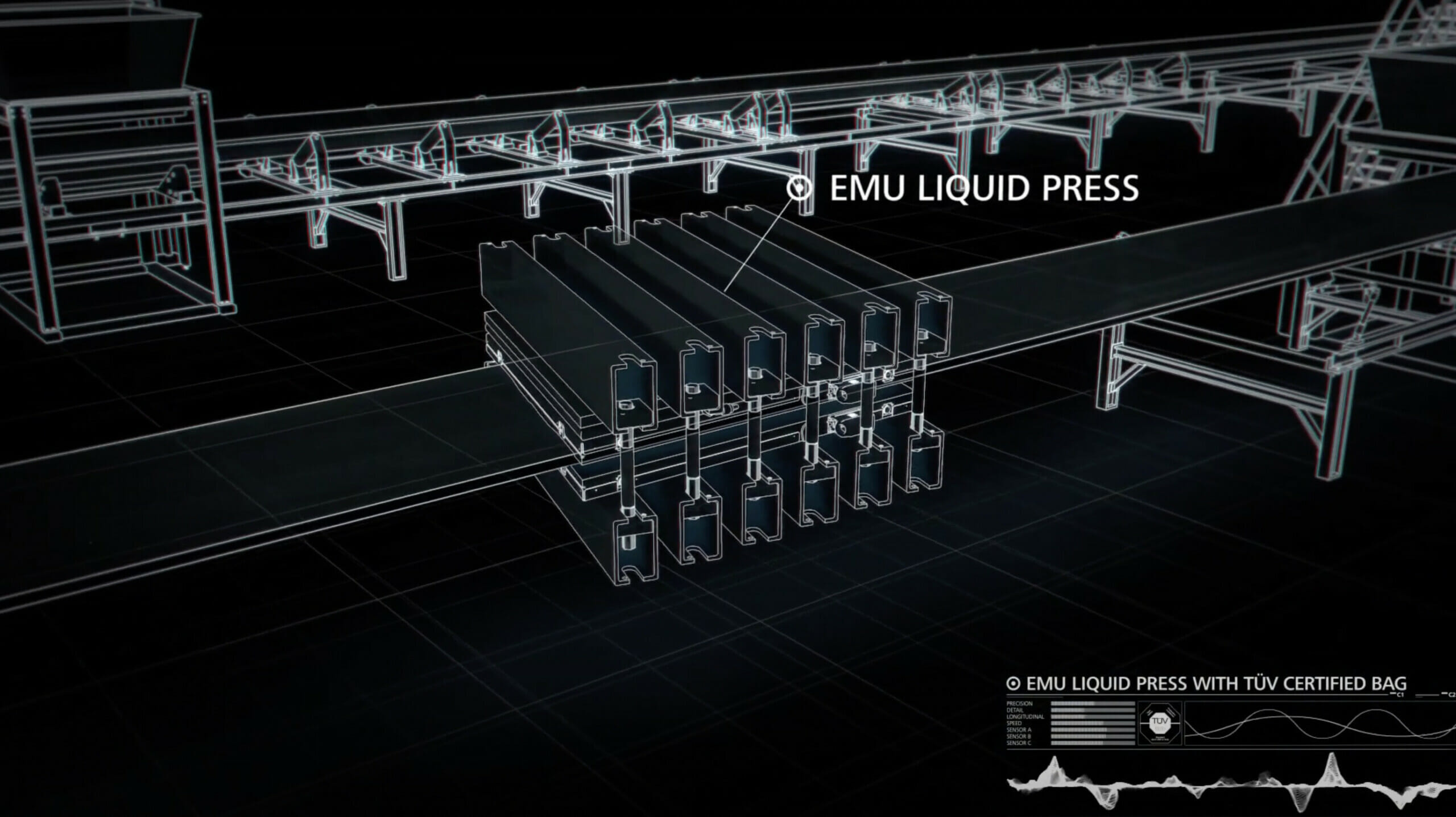

EMU Liquid Press Video Demo

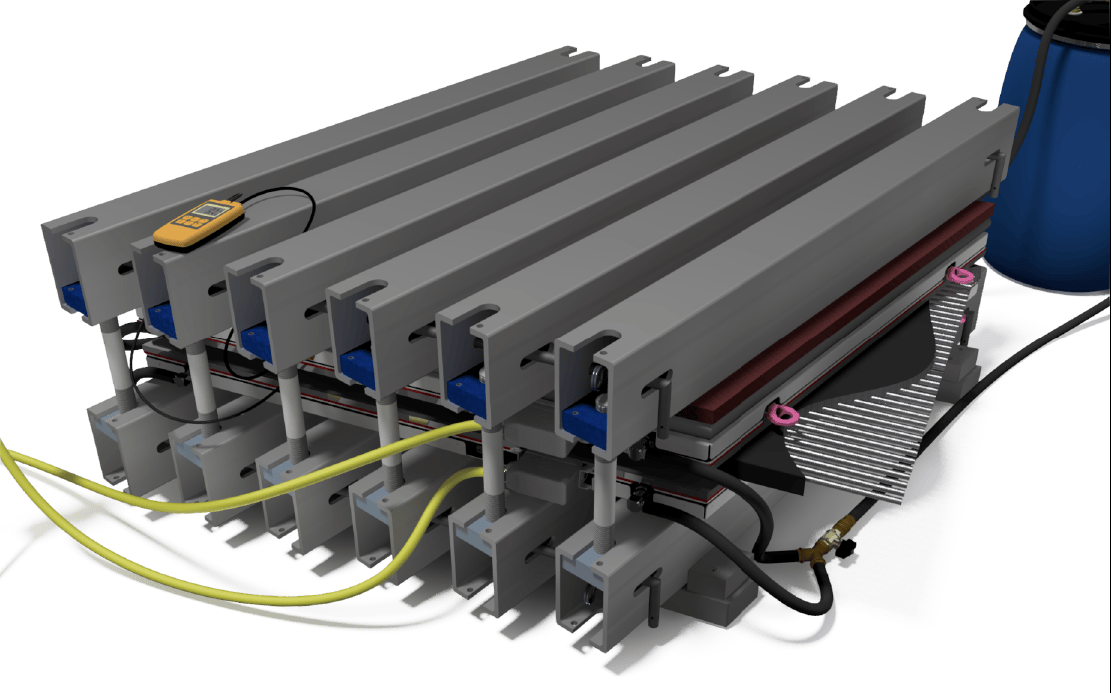

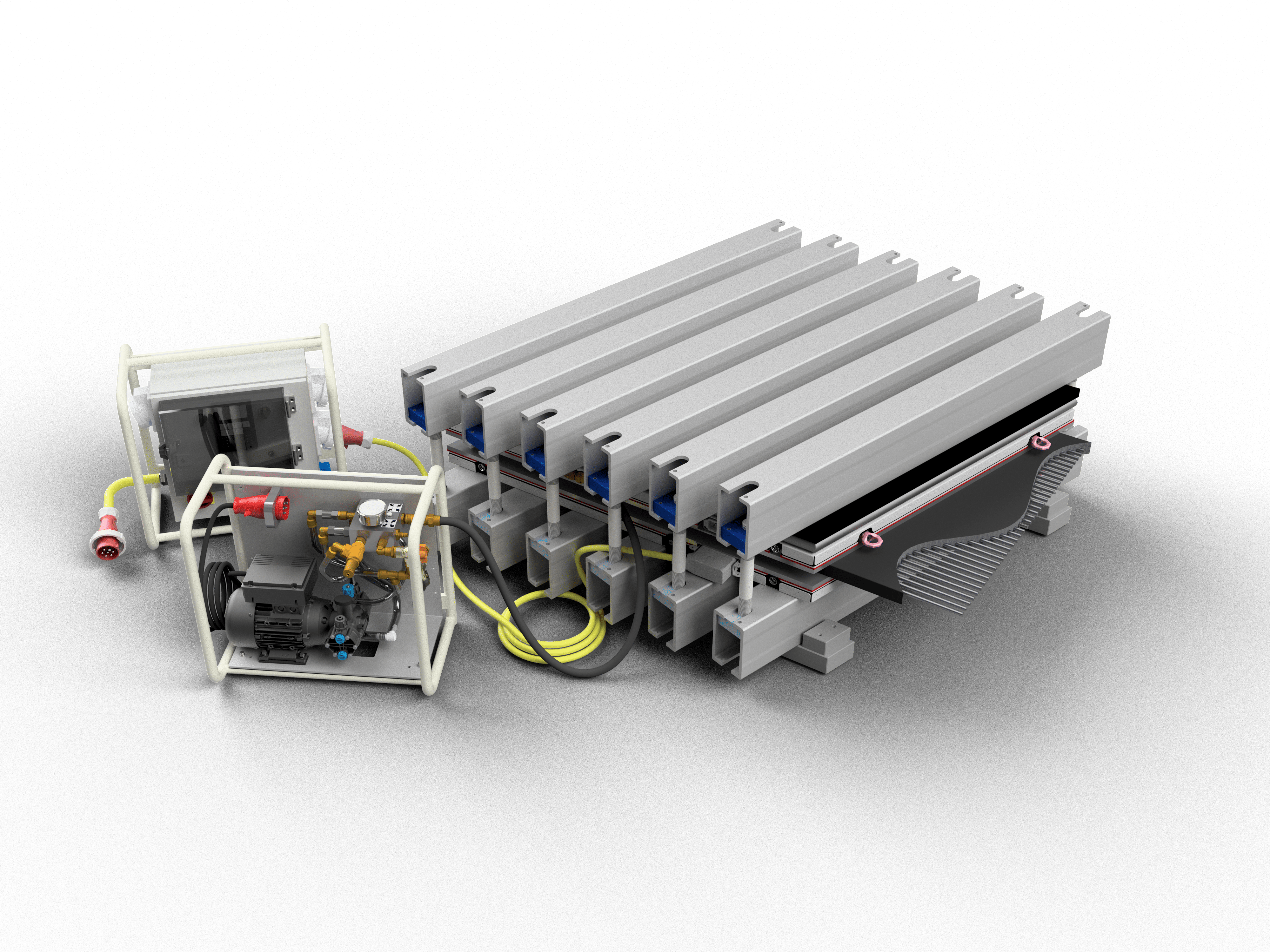

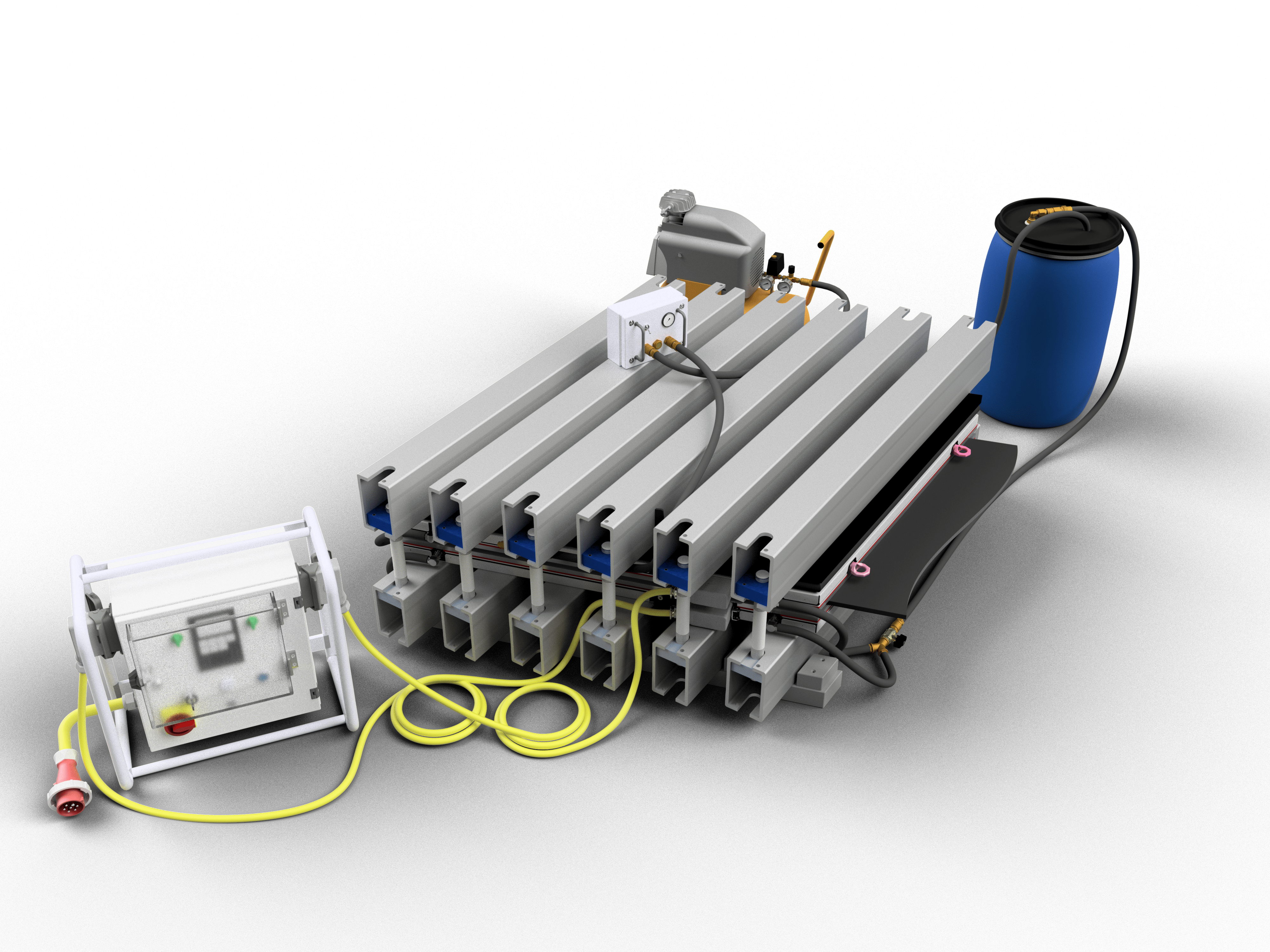

EMU-LIQUID vulcanizing press

The EMU-LIQUID vulcanizing press operates with a liquid pressure system for fast and efficient splicing of fabric and steel cord belts. There are various pressure pump models available to be used with this press.

- Pressure medium: water

- Pressure range: 70 – 140 N/cm² (100–200 psi)

- With safety valve and pressure gauge

- Also suitable for draining pressure bags

- Optional safety restraints and lifting lugs for traverse bars / cross beams.

EMU-AIR vulcanizing press

The EMU-AIR vulcanizing press utilizes air pressure via an air control system for fast and efficient splicing of fabric belts.

- Surface pressure up to max. 70 N/cm² (100 psi)

- With safety valve and pressure gauge

- Optional safety restraints and lifting lugs for traverse bars / cross beams.