Overview

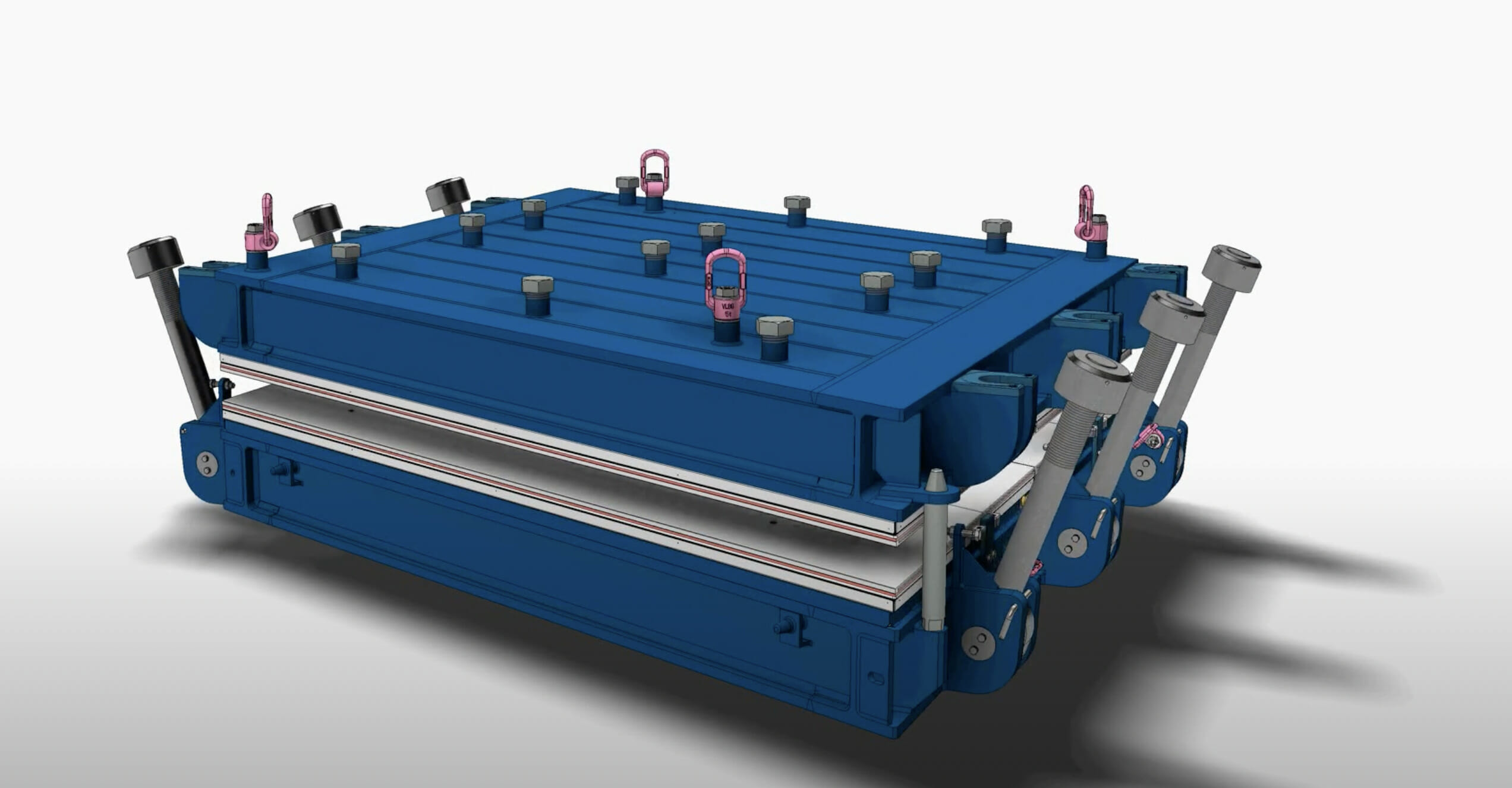

Vulcoframe Vulcanizing Press

Vulcoframe Vulcanizing Press

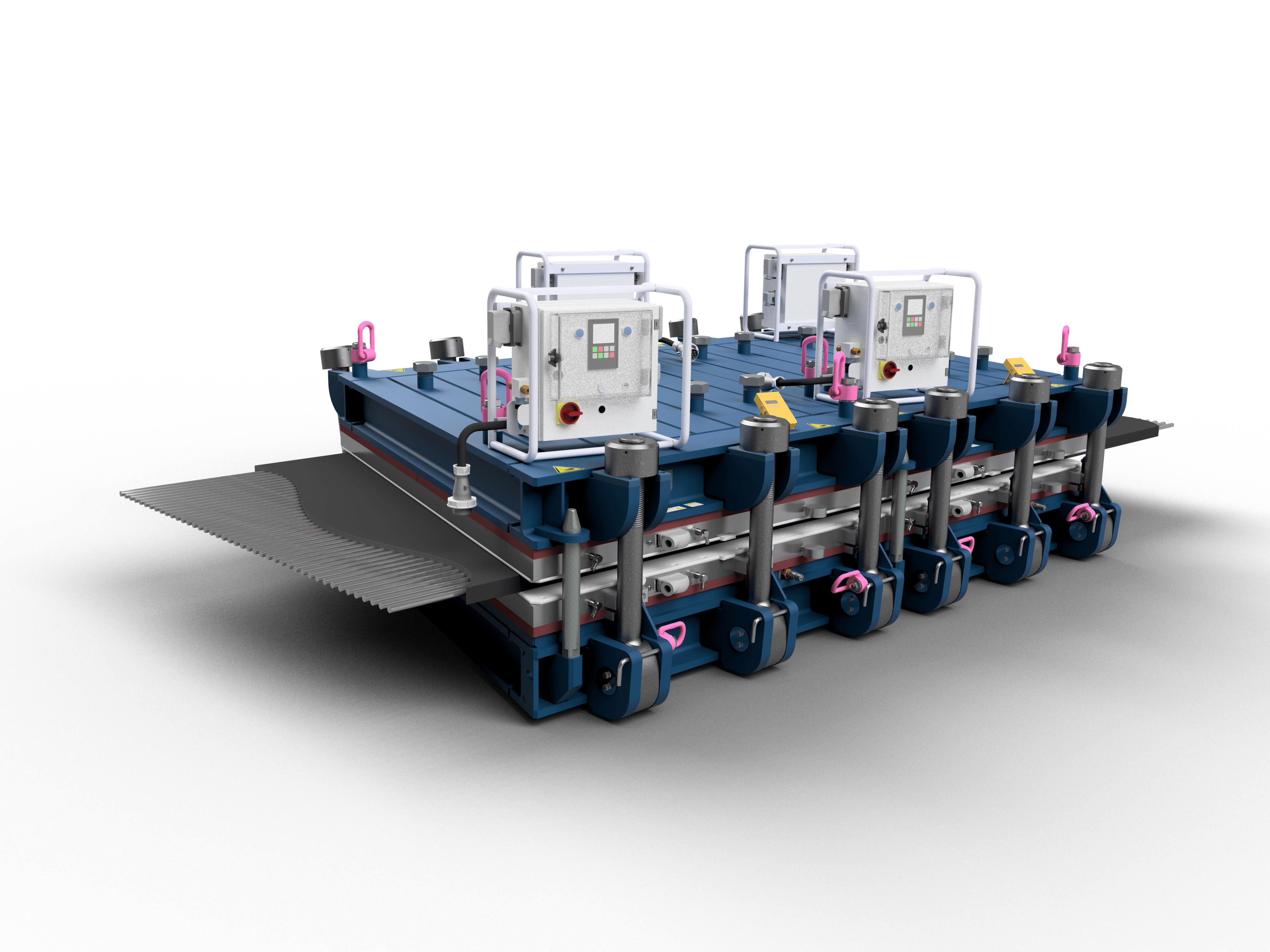

The WAGENER Vulcoframe is a heavy duty two-piece vulcanizer with separate electrical control suitable for belt widths from 1600mm to 2800mm using a maximum pressure of 200Psi on a bias of 22°.

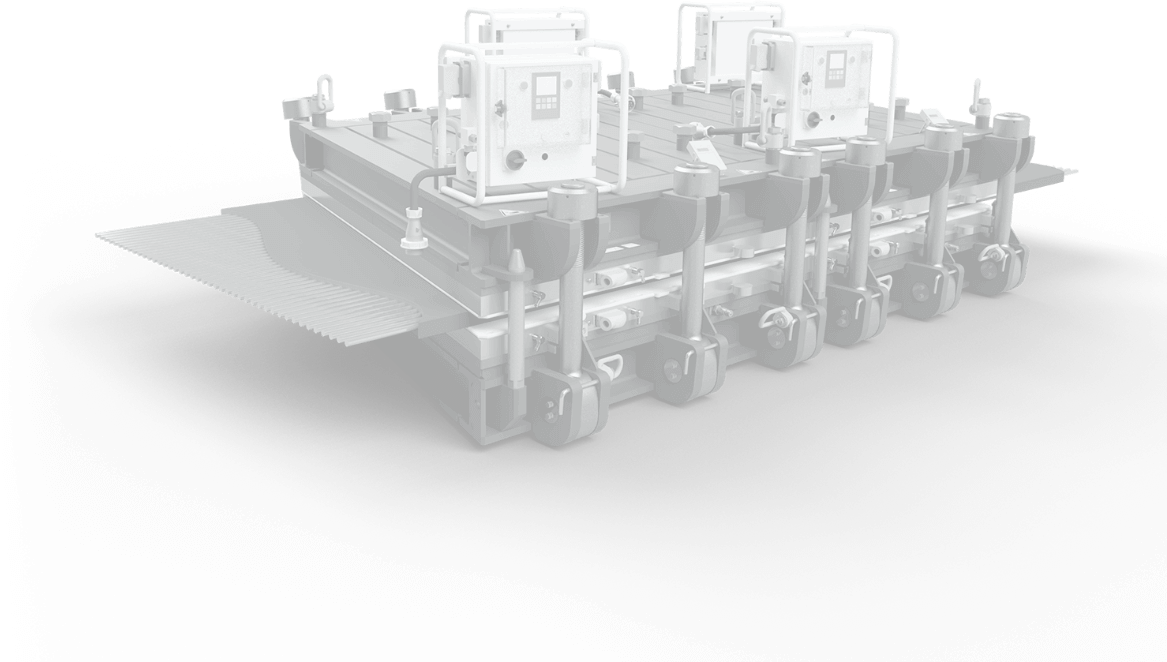

The Vulcoframe is designed for the splicing of steel cord and fabric belts even under the toughest and most rugged conditions. Engineering and production Made in Germany. Quick assembly and disassembly and reduced downtimes because of the two-piece vulcanizing press design.

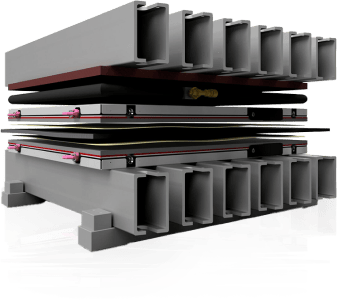

- Solid steel framework with low overall height with greatest strength due to strong HEM220 wide flange beams. With at least double safety against deformation and a maximum deflection of 10 mm (on our press model J22).

- Sturdy traction bolts for mechanical or hydraulic operation, mechanical limitation of the pivoting traction bolts at approx. 20° (pl. see 3-D-animation below). Optional rotation dampers on the swiveling traction bolts.

- Removable traction bolts (Option A): VULCOFRAME vulcanizing presses can be supplied complete with quick release pins holding the bolts to the bottom section of the vulcanizing unit, allowing the bolts to be removed along with the top of the press. This process has the effect of removing trip hazards within the splice station and increasing safety.

- Safety traction bolts (Option B): VULCOFRAME vulcanizing presses can be supplied complete with additional rotation dampers to prevent uncontrolled swiveling out for more safety at work when the traction bolts are permanently mounted on the bottom part. In this case, the traction bolt can be moved downwards slowly and safely.

- Tested and DGUV/DNVGL certified lifting points on the upper part, suitable for the transport of the entire press as per DIN German standard. High safety standards apply as the lifting points can be used up to 14 ton whereas the entire press weight is about 8 ton (on our press model J22).

- Uniform pressure distribution by means of aramid reinforced pressure bags (TÜV certified).

- Clearly visible and solid centering pins on the lower part simplify correct setting down of the press upper part.

- Massive edge bar pressing device on the lower part for best splicing results.

- Integrated water-cooling system for quick cooling.

- Electric plug integrated in the heating platen for easy replacement of the heating platen.

- Durable glass fibre reinforced insulation.

- Electronic temperature and pressure monitoring with optional SPLICE WATCH datalogging technology for monitoring and recording of the whole vulcanizing process.

- Control boxes can be designed and manufactured in Australia to meet and exceed the requirements of AS4871/3007/3000 and 2081 for use in surface mines and quarries, including underground non-hazardous areas.

SEE IT AT WORK

VULCOFRAME two-piece press 3D animation