WACOCUT

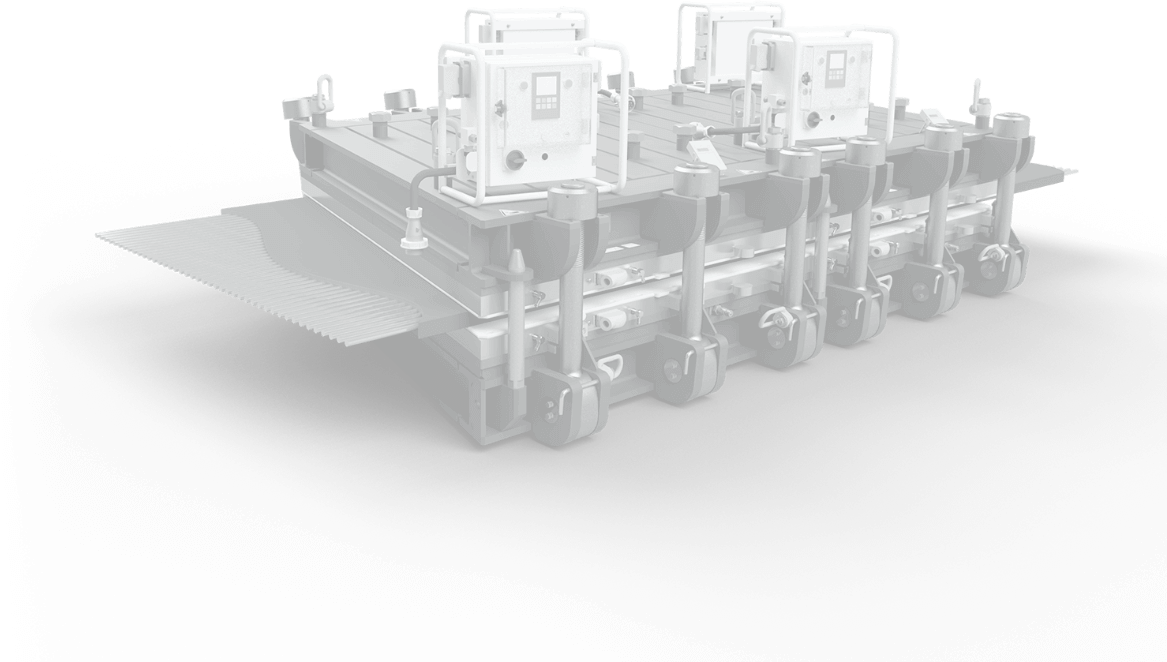

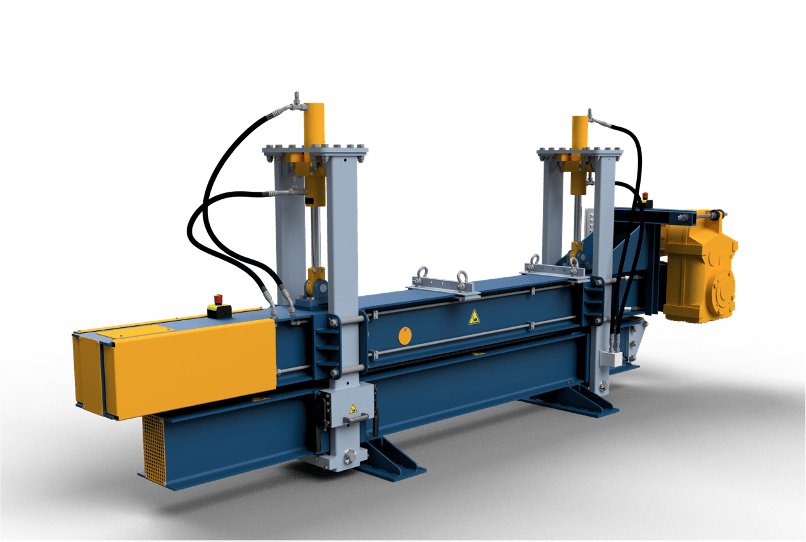

The WACOCUT is specifically designed for efficiently cutting a wide range of conveyor belts, especially steel cord belts, in the shortest time possible.

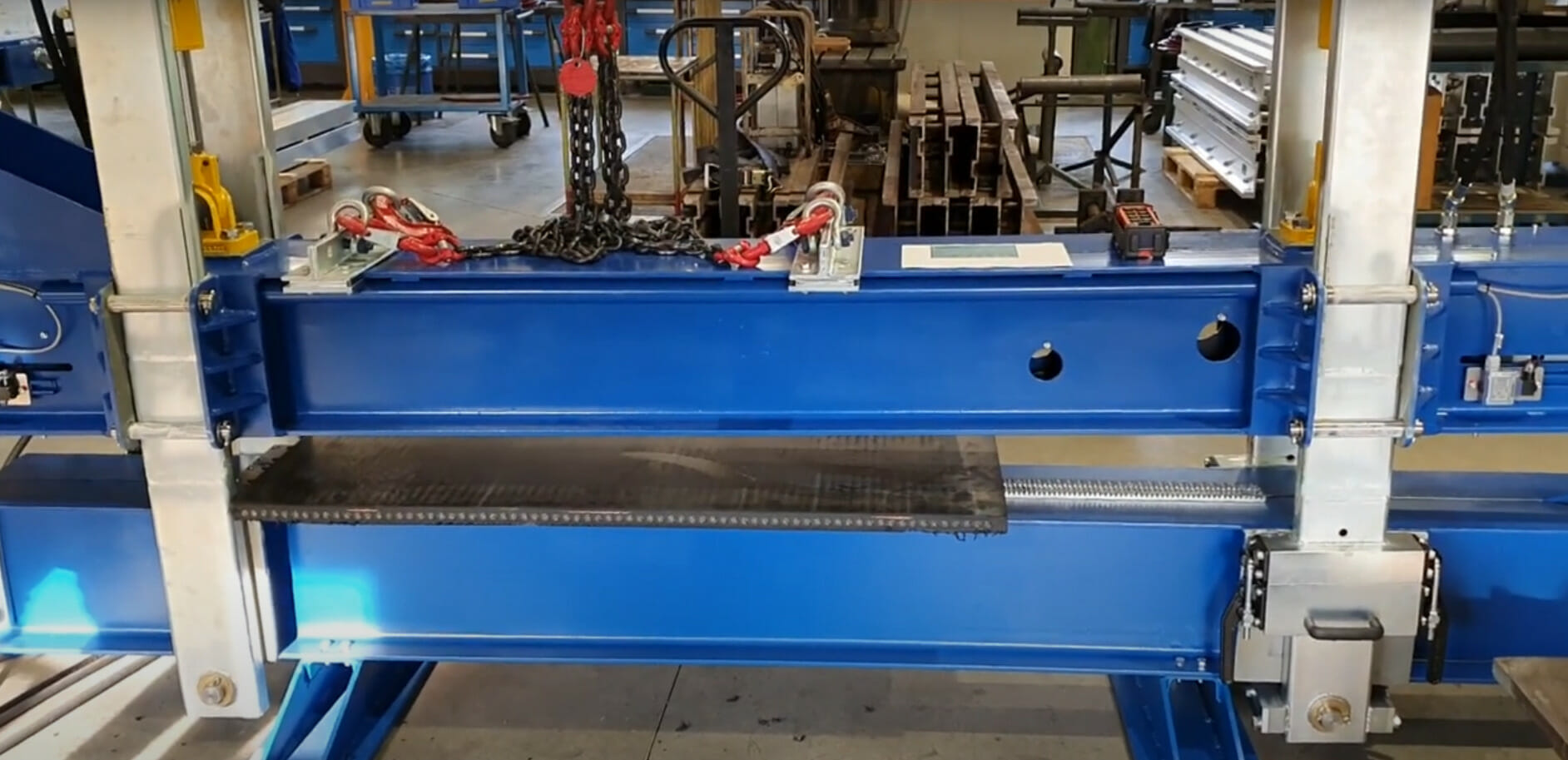

The WACOCUT is intended for stationary and mobile use. In case of stationary use, the belt clamping frame is opened parallel and the conveyor belt is pulled into the belt clamping frame. In case of mobile use, the belt clamping frame is suspended from the crane and opened scissor-like and moved into the belt conveyor.

Alternatively the belt clamping frame standing on the ground with mounted wheelsets can be opened scissor-like and moved into the belt conveyor. For this purpose a rail track is to be provided by the customer.

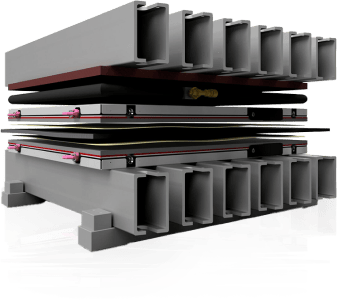

The WACOCUT consists of the following components:

- Belt clamping frame

- Electronic control box

- Hydraulic unit

- Simple and safe handling with high cutting force

- High operational safety due to the unique design

- Fully-automatic cutting process

- Emission-free working (low noise level, no sparks, no smoke, no air pollution)

- Low staff requirements

- The cutting tool can be used in closed rooms without any concerns

- Designed for the stationary use in workshops and for the mobile use in all conveyor belt installations

- The WACOCUT can be opened parallel or scissors-like (crocodile type)