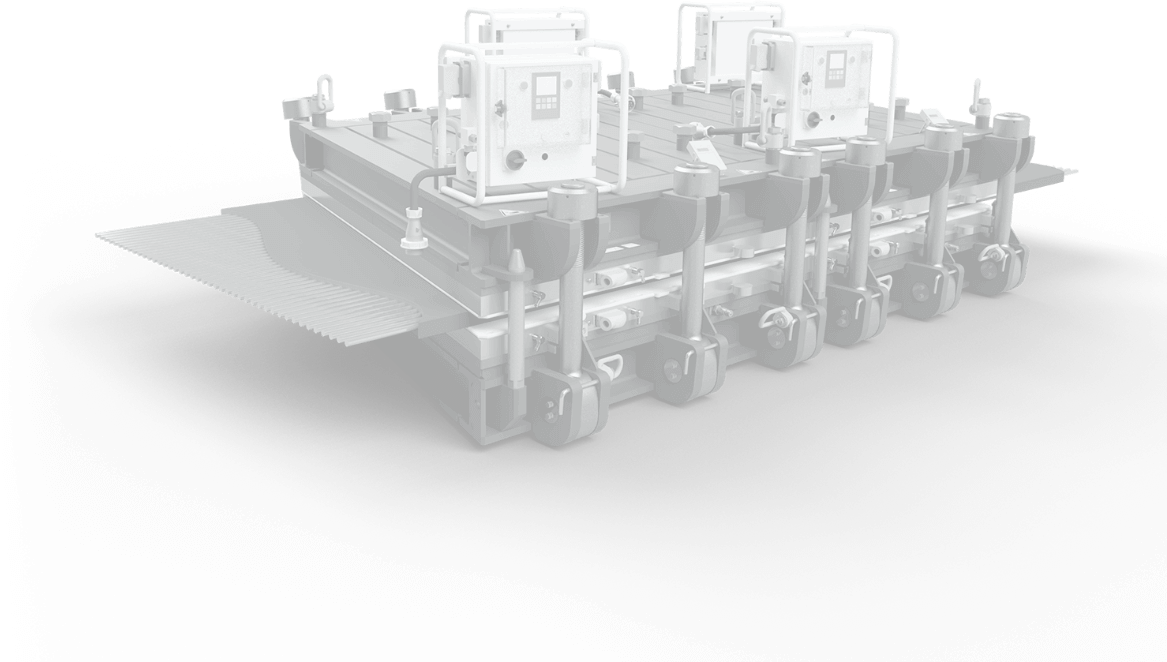

the new force in vulcanizing technology

for the Australian Mining Industry.

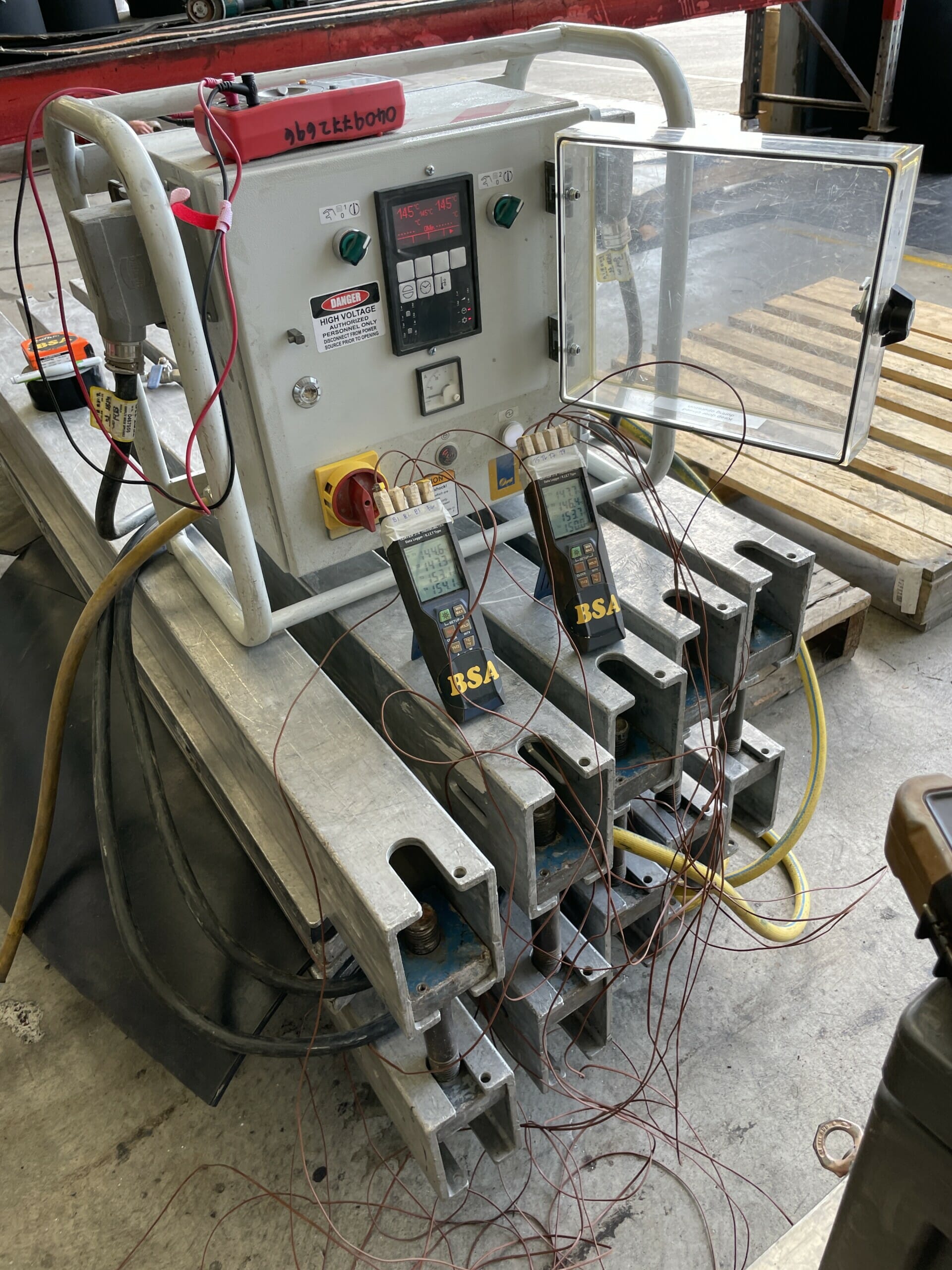

WAGENER Vulcanizers Australia offers comprehensive maintenance programs for all vulcanizing press equipment, whether onsite or at our facility, carried out by our skilled professionals. This ensures the longevity and optimal performance of your essential capital equipment.

WAGENER Vulcanizers Australia Routine Maintenance Program is designed to assist all customers to keep their valuable capital equipment safely performing to OEM requirements. We can provide servicing plans for new vulcanizing press equipment and refurbishment, upgrading and repair for older equipment. Employing our service program is an investment in the future value of your WAGENER Vulcanizers asset.

Advantages of the WAGENER Vulcanizers Routine Maintenance Program.

Regular maintenance

WAGENER Vulcanizers can establish a maintenance schedule to assist all customers with creating routine maintenance tasks, such as functional and temperature testing including resistance testing for electrical hardware and dry lubrication of moving parts. We can provide regular yearly inspection and certification of your vulcanizing equipment in house and on site.

Extended equipment lifespan

WAGENER Vulcanizers Routine Maintenance Program can help identify and address issues early, preventing major breakdowns and extending the lifespan of the vulcanizing unit, reducing the need for costly replacement.

Improved safety

WAGENER Vulcanizers Routine Maintenance Program when implemented provides a vulcanizing unit that is less likely to malfunction or cause damage to the splice, the repair, people or plant. This enhances workplace safety by reducing these risks.

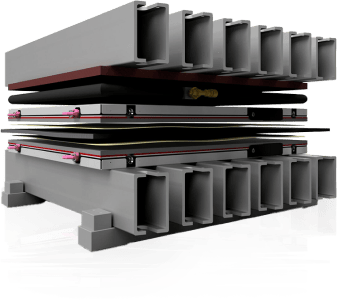

Did you know? A vulcanizer suitable for a 1200mm wide belt, pressurized to 180 psi potentially has the same stored energy as a delivery van hitting a pedestrian at a speed of over 130 km per/hr.

Consistent performance

WAGENER Vulcanizers Routine Maintenance Program ensures your vulcanizer operates consistently and efficiently. This results in higher quality belt splices and repairs, improving overall conveyor performance.

Reduced downtime

WAGENER Vulcanizers Routine Maintenance Program can offer scheduled maintenance that can be completed during off-peak times to minimize production downtime. This program assists with maintaining productivity levels to meet production schedules.

Cost savings

WAGENER Vulcanizers Routine Maintenance Program, implemented properly, have the potential to be more cost effective than reactive repairs or emergency replacements. By addressing issues before they become critical , reducing overall repair and replacement costs.

Compliance with standards

WAGENER Vulcanizers Routine Maintenance Program provides an opportunity to ensure your vulcanizing unit is maintained to relevant Australian Standards, reducing the risk of regulatory violations.

Enhanced efficiency

WAGENER Vulcanizers Routine Maintenance Program ensures your vulcanizing unit operates at peak efficiency, requiring less time and energy to complete belt splicing and repairs. This can lead to energy savings and increased productivity.

Operator training

WAGENER Vulcanizers Routine Maintenance Program, when performed on site offers an opportunity to train operators in correct vulcanizer operation increasing safety, while enhancing their skills and knowledge. Press operational safety training is available upon request.